Our Engineering offices are located in Sharjah - UAE, Doha - Qatar and in Chennai, India.

EVERSENDAI has an in-house design team of highly dedicated qualified engineers and detailers having vast experience in modeling, analysis, design, application and value engineering in the following areas.

• High Rise buildings

• Industrial Structures

• Stadiums

• Bridges

• Airports

• Shopping malls

• Infrastructure Projects

Salient Features of the Division:

• We are specialized in early release of Steel through involvement of Designers and Detailers to produce Shop drawings and 3D models right at the Conceptual stage of the project. Early Release of Steel shortens the project schedule.

• Unique capability of providing Pre-Detailed Shop Drawings as well as manufacturing drawings under one roof enhances one stop shop for all client needs.

• Develop solutions profound with Design information as part of the Total Project Execution.

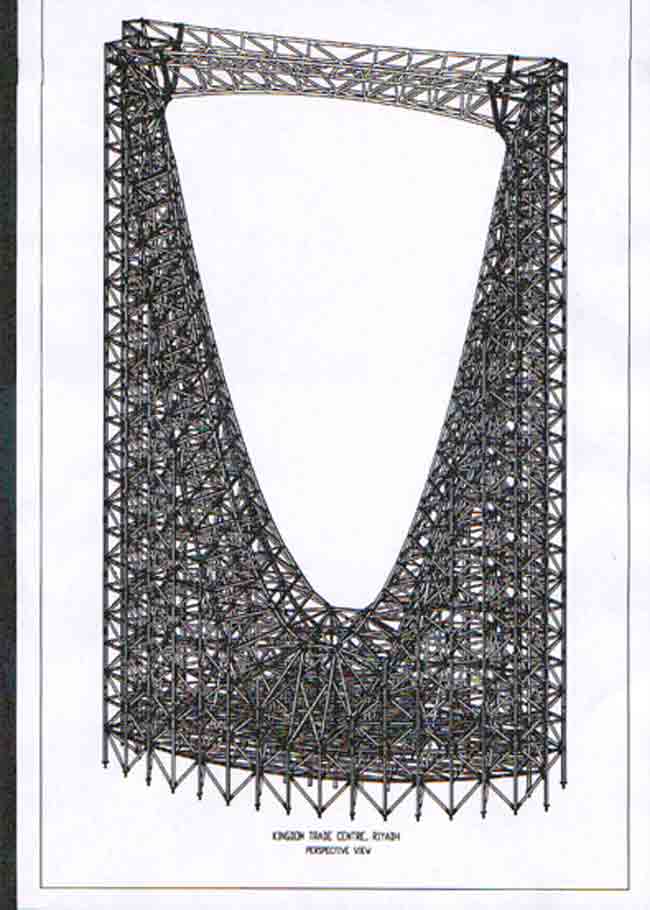

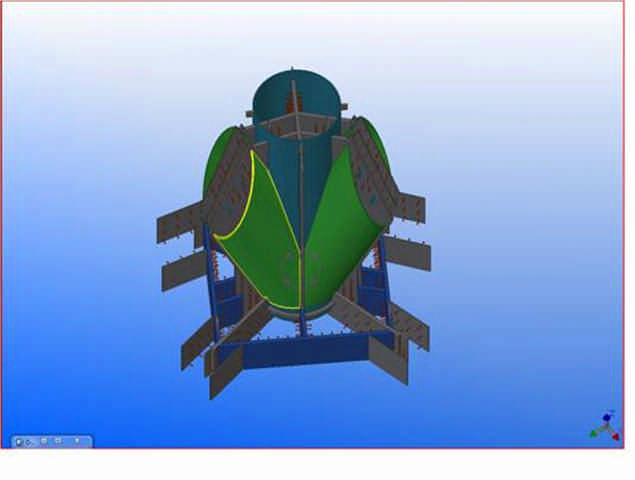

• Value engineering with economical and fabrication & erection friendly Connection Details and Innovative Erection Schemes resulting in benefits to Project.

• Specializes in developing efficiencies of volume through repetitive design with many identical or similar assemblies resulting in Construction efficiency.

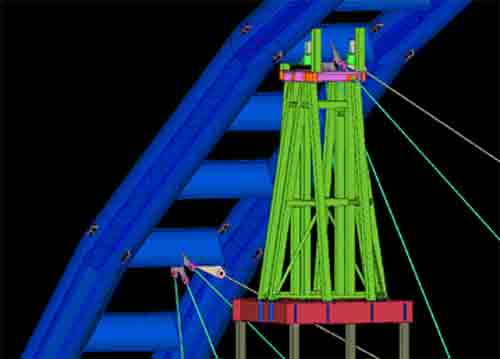

• Erection / Temporary Engineering- Determining Center of Gravity for intricate assemblies, which in turn is used for the development of erection schemes to provide detailed plans for Complex Lifts, reducing the risk of Operatives working at height.

Strength of the Division:

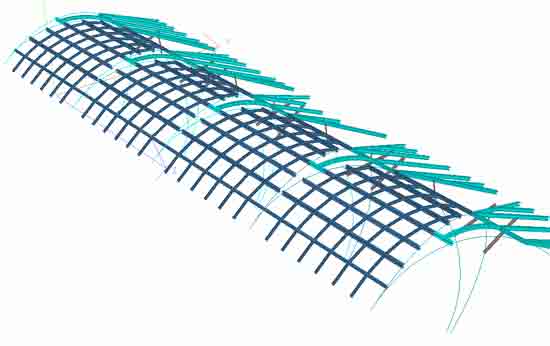

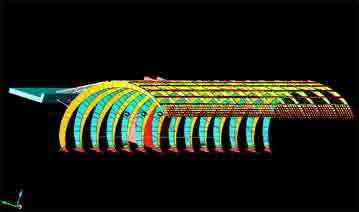

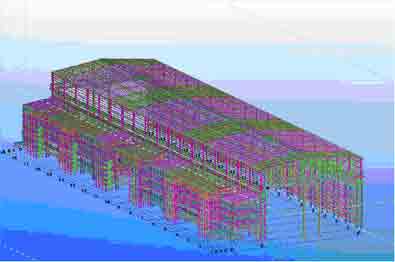

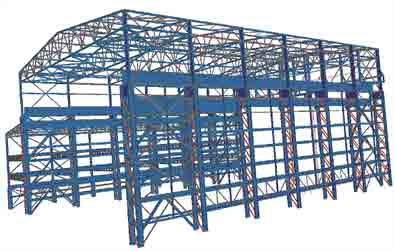

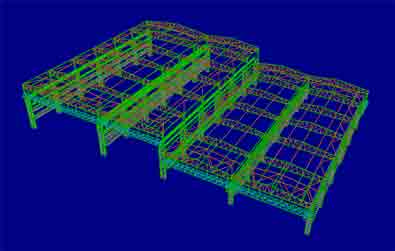

• Unique modeling technology for improved Quality and Profitability Solutions provided are CNC compatible and tailored to meet the Shop needs

• Developing of 3D applications that allows us to meet our client needs with “On-Time Delivery”, “Accurate”, “Easy to read” drawings

• The 3D modeling is used throughout the Project's early development through to its on-site erection by giving GA's and Manufacturing drawings.

• Constantly monitor, evaluate & improve the Project Management technology & Project delivery systems.

• Engineering drawing procedure for exacting tolerances to ensure the assemblies are safely and accurately erected at Job site and satisfy the critical interfaces with other finishes and trades.

• Drawings are produced for Control Assemblies of many complex structures so that it is built up accurately in the shop to ensure the fit up of all components are exact when the assembly reaches the job site.

• The flexibility to fabricate and sub-assemble the large complex structures before being shipped to Job site.

• Frequently brought financial benefits to projects by the development of innovative erection schemes for the complex structures we manufacture.

• Engineering Expertise with International Codes of Practices like IS, BS, AISC, Australian, Canadian.

• Good relationships with Research and Academic Institutions

We are equipped with software's such as STAADPRO, ETABS, FASTRAK, DESCON for Structural Design and custom made spread sheets for Connections and TEKLA STRUCTURES, BOCAD, RC-CAD and ACAD for Structural Steel and Rebar Detailing.

We have more than 30 experienced Design engineers and 120 Detailing personnel including experienced modelers and checkers along with 30 Supporting Staff. The average production capacity is 7000 to 8000 metric tonnes per month.

Continuous recipient of many awards such as Golden Award for Best and Complex Model from Tekla Structures for various projects.

Electronic communications with dedicated 24 hours, 7 days a week FTP server with high speed internet connections and voice over internet protocol (VOIP) across the region.

|